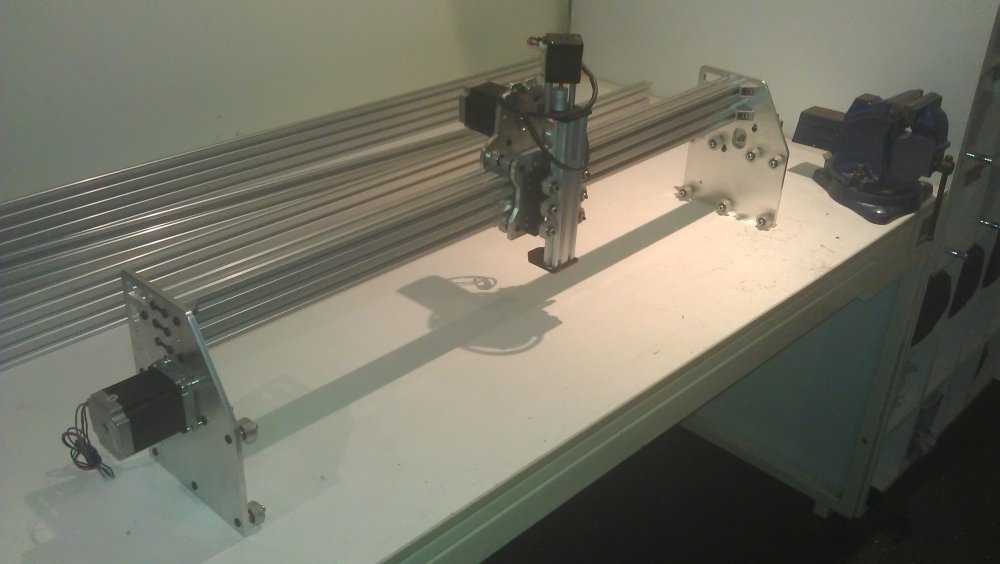

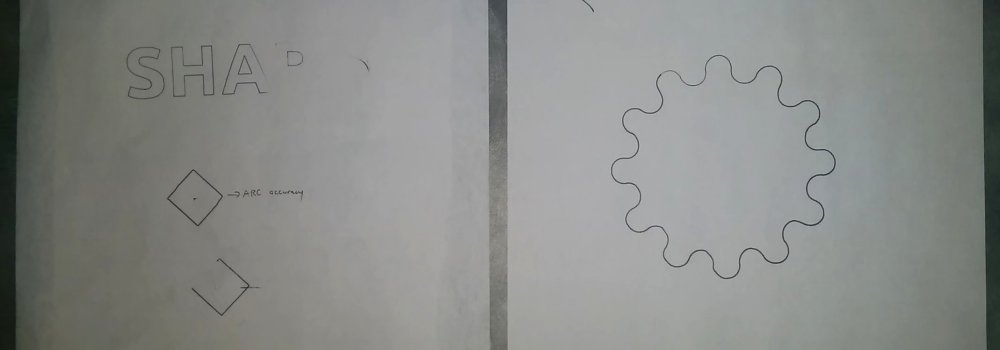

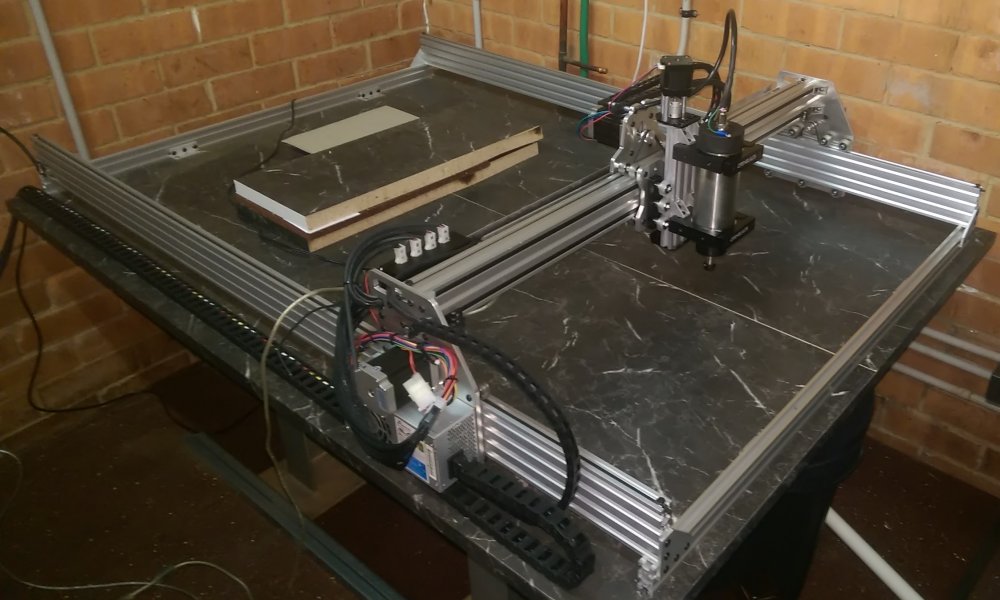

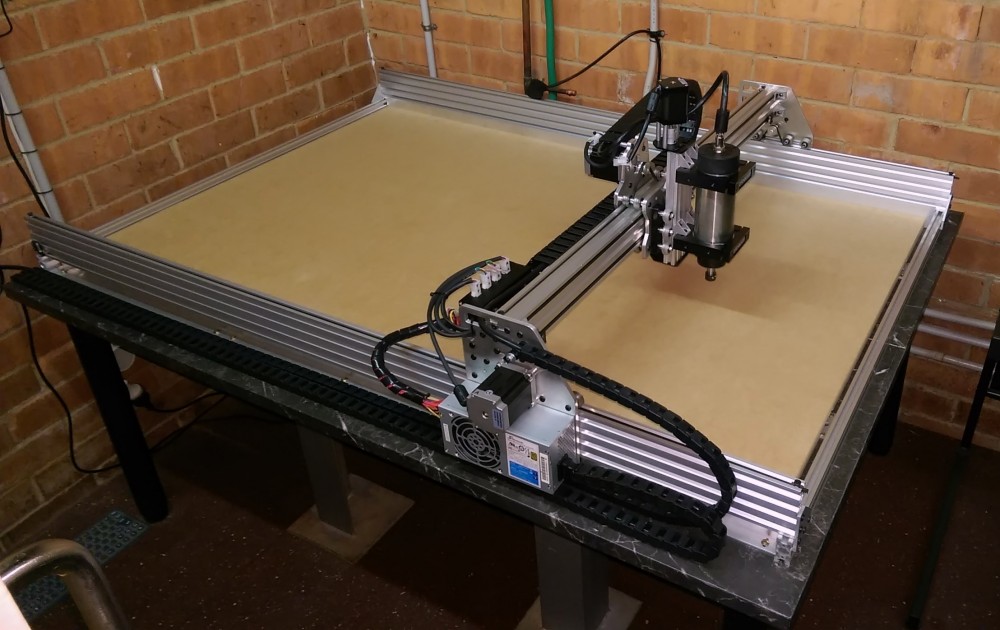

Got a fair bit done over the christmas/new year break - equally spent finishing off the hardware and learning the software.

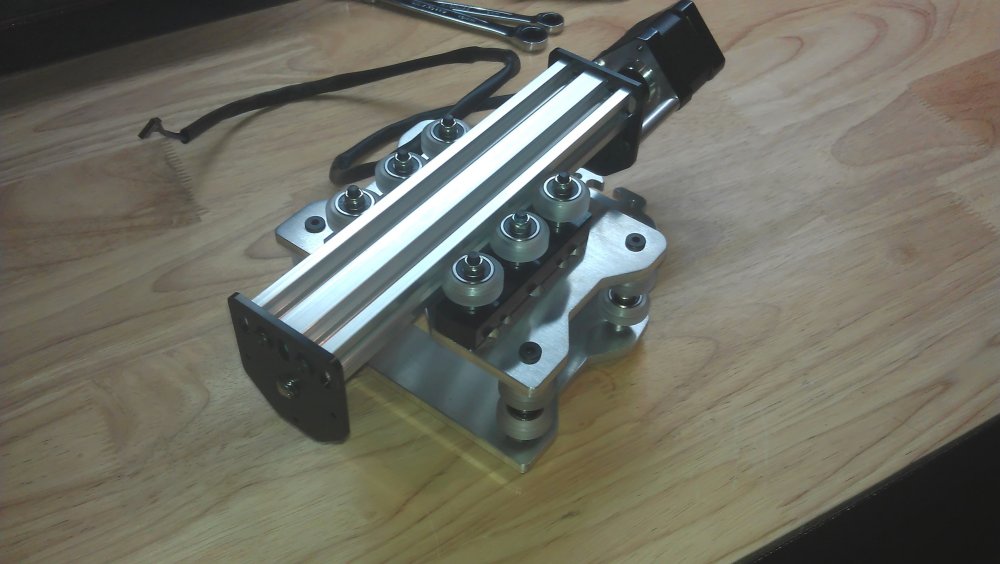

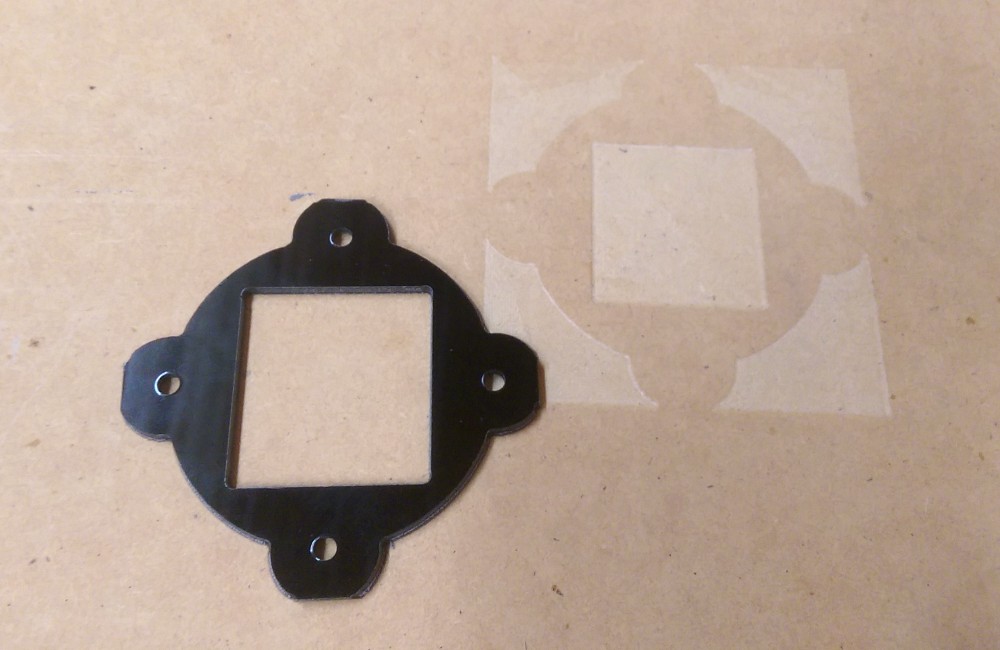

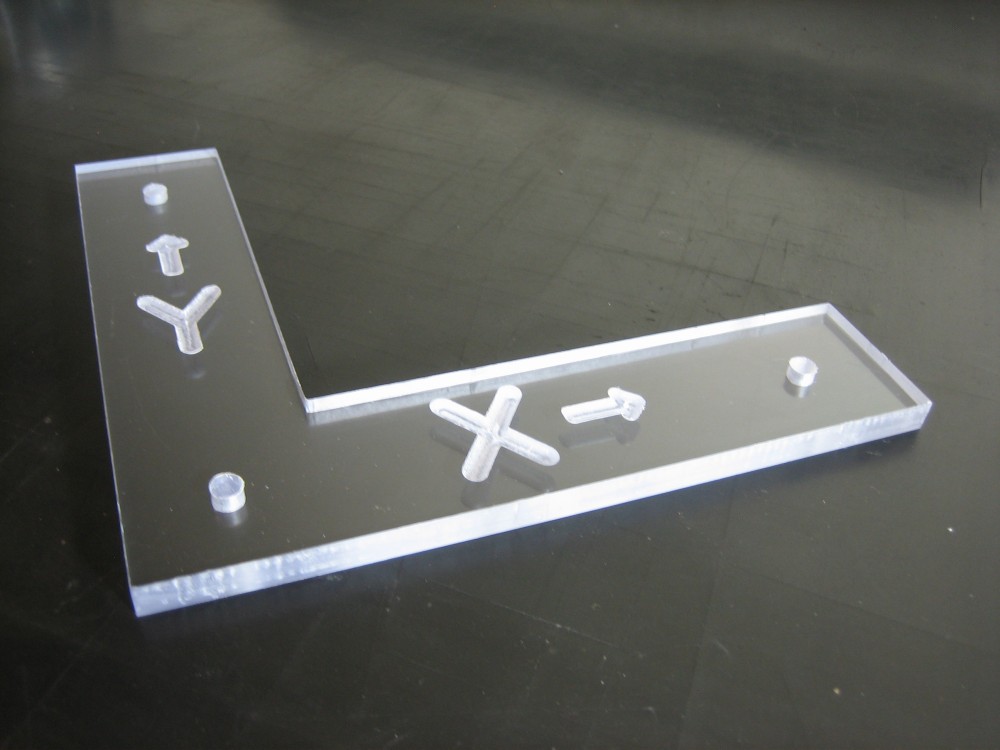

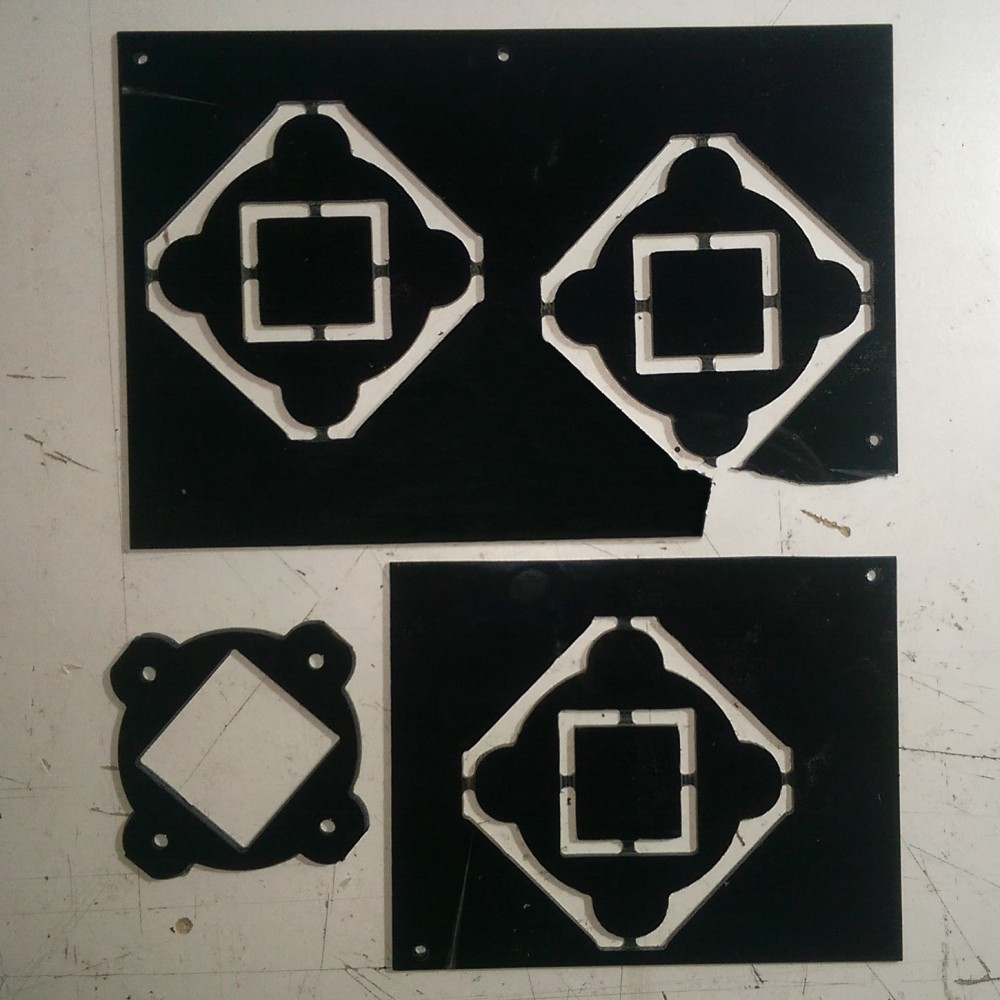

I had a couple of goes at designing and machining some brackets for the torch I'm working on. I used Autodesk Fusion 360 for the CAD/CAM, which is currently free for non-commercial/hobbyist use. It takes a bit of time to learn but seems to be more powerful than I'll ever need.

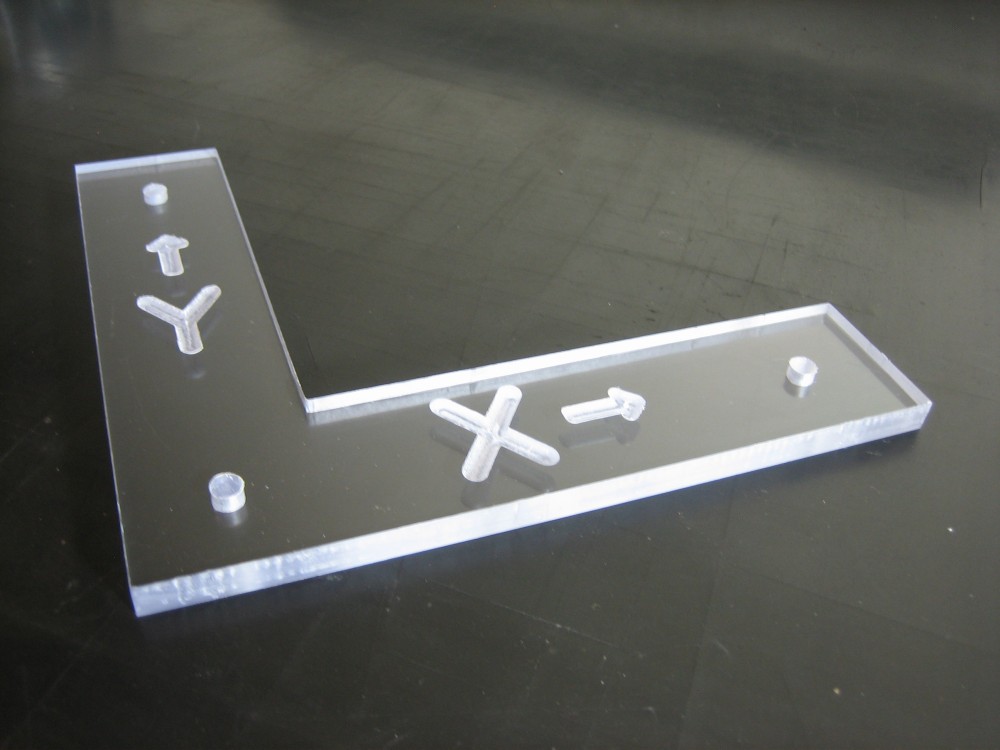

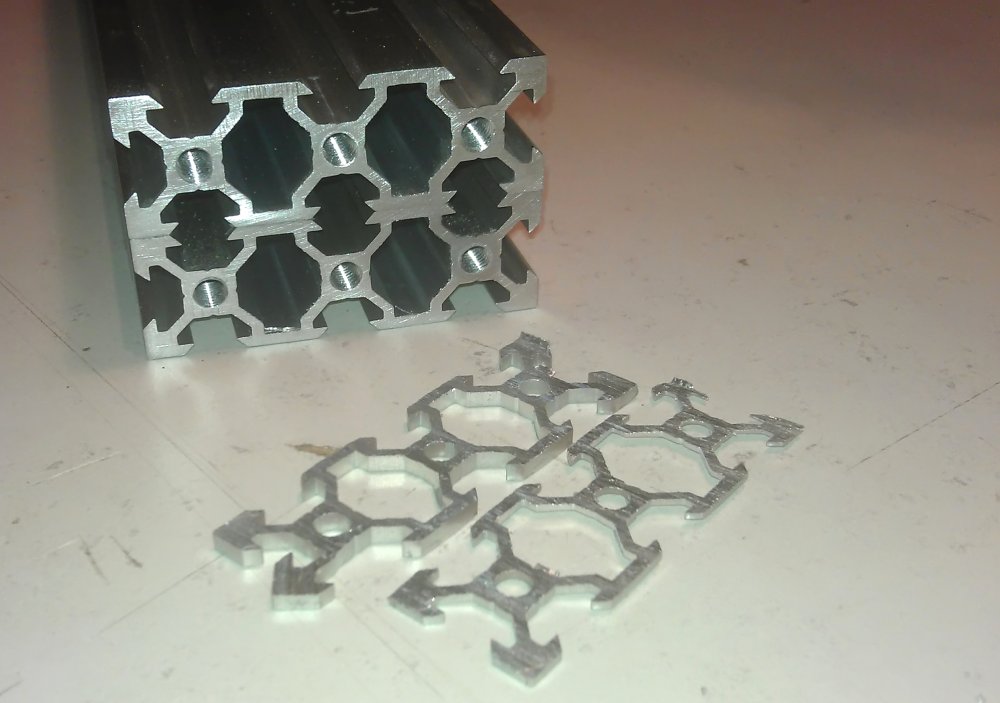

The first attempt failed as I didn't set the stock bounds beyond the bracket model, so the edges got squared off. It was also machined really inefficiently. For example, the entire section in the middle was machined when it didn't need to be.

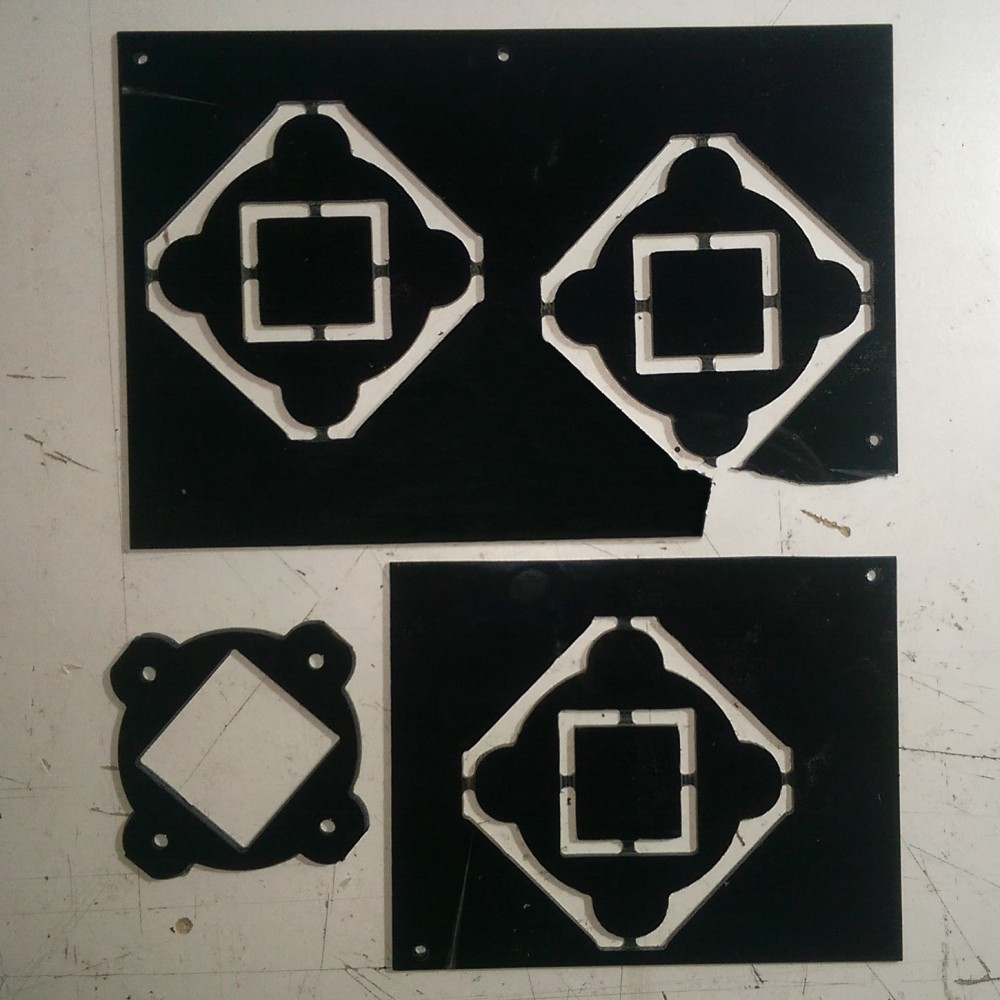

For my second attempt, I added areas to the model to exclude for machining, and added tabs so that the part didn't move. I have since found out that this step isn't necessary - Fusion 360 will do this for you if you select "2D Contour" machining rather than "2D pocket".

The photo below also shows as issue which occured during machining. At the beginning and end of the program, the machine moved to the origin without retracting the bit to a safe distance. The bottom-right piece has a gouge on its bottom-left where the bit dug into the acrylic at the start of the program. The top piece had the bottom-right corner snapped off when the bit hit the acrylic at the end of the program at high speed. The problem was caused a G28 (go to home) command in the generated g-code. Since I'm using soft limits (no hardware limit switches yet), this command just moves to the point where the machine was powered on. Creating a custom Fusion 360 post-processor with a G1 (move) instead of G28 solved the problem.

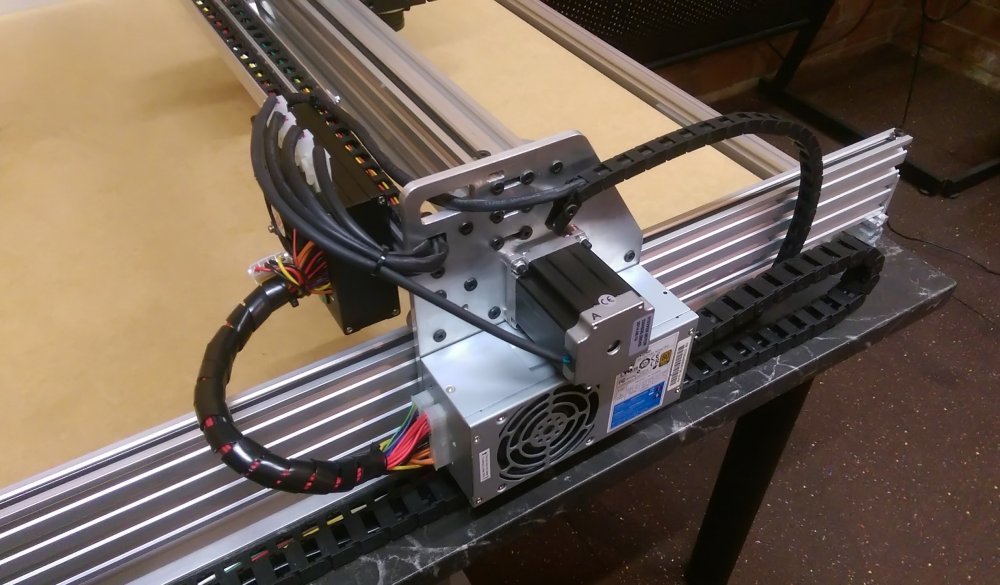

I also installed a compressed air nozzle to flush chips away from the bit. The compressor is a generic 90L/min aquarium pump. I opted for this kind of pump as they're designed to run 24/7, so should easily handle long runs. I installed the pump underneath the CNC table on rubber mounts, to reduce vibration. The air hose runs up the wall to a swinging gantry and then comes down into a flexible arm. The bracket was 3d printed to fit snuggly against the X gantry.

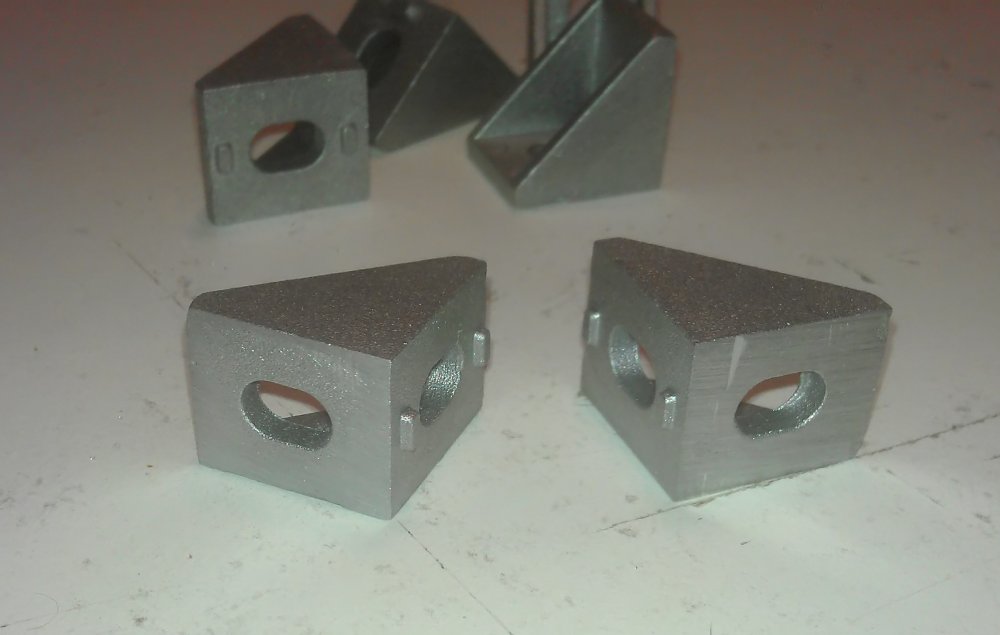

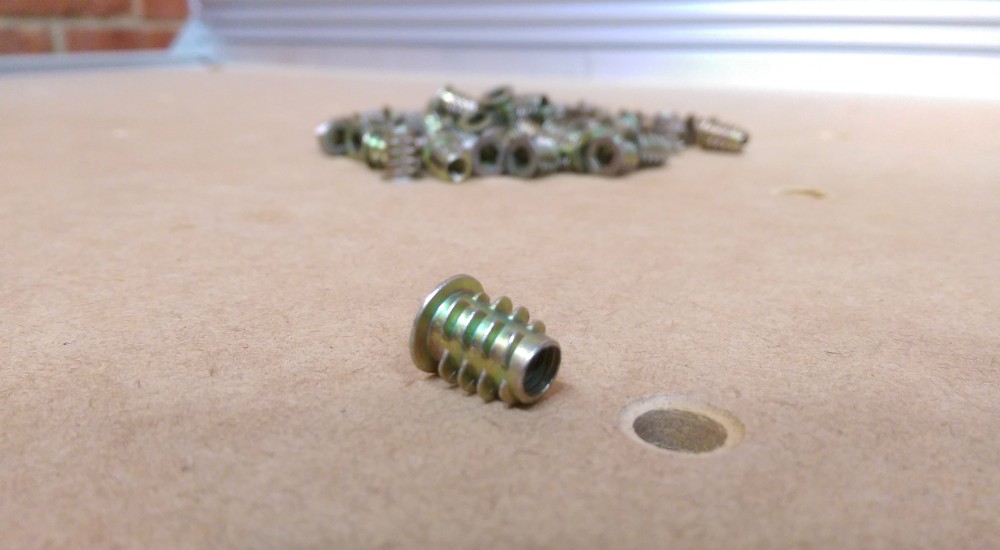

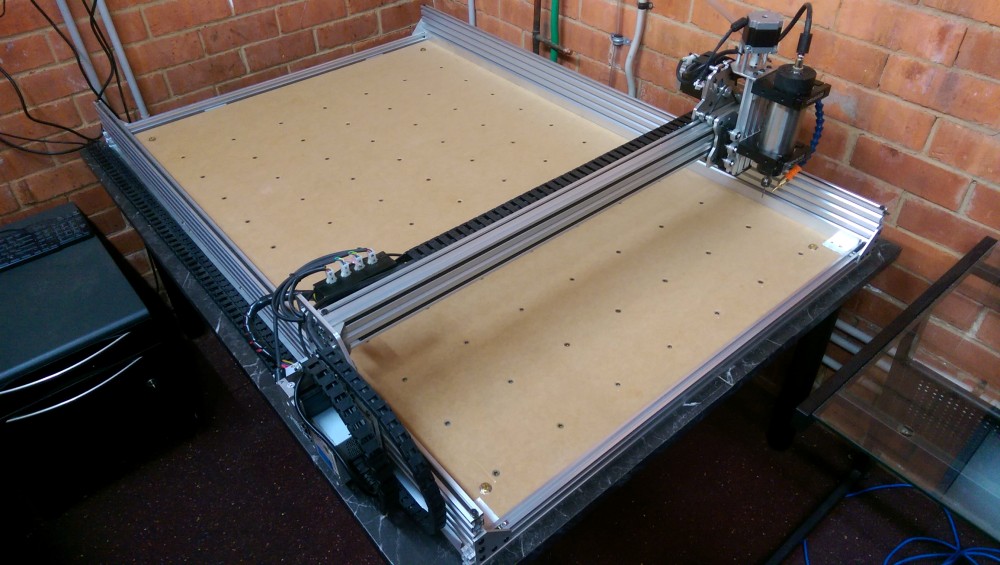

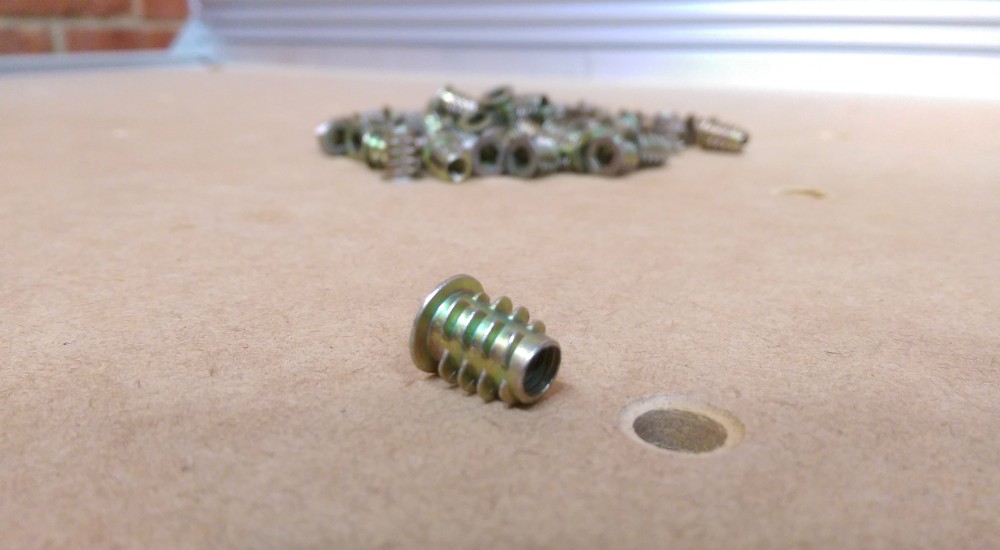

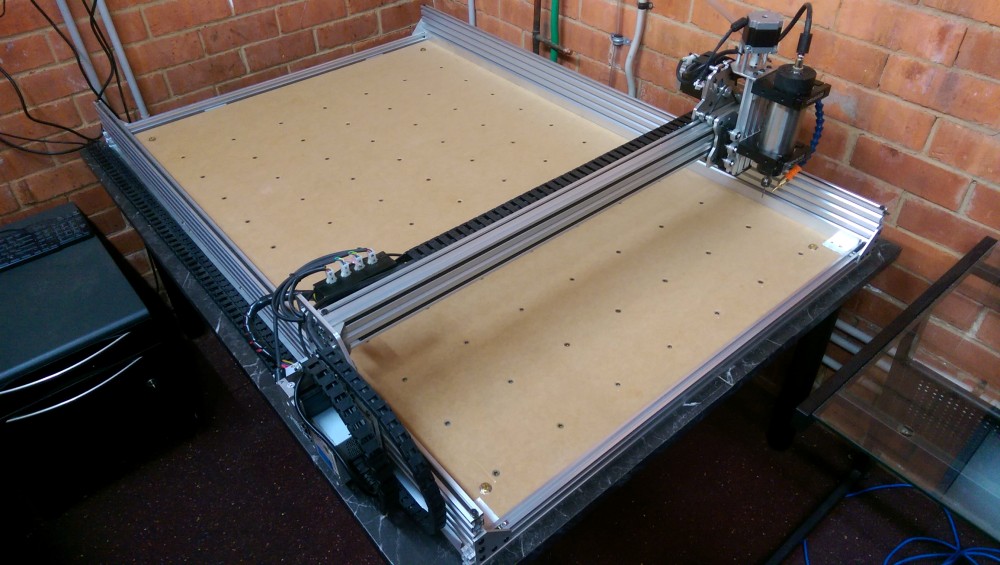

For the test carvings above, I screwed the arylic to a sheet of MDF and then clamped this to the table. This isn't a workable solution long-term, so I needed a better way of fixing the work piece to the bed of the CNC. The two most common methods seem to be T-slot tracks in the bed, or use of threaded inserts. I opted for a grid of 7x11 threaded inserts, as it was cheaper and didn't require me to re-do the CNC bed. Accurately drilling and counter-sinking 77 holes would have been a pain, but luckily I have a CNC to do the boring work. :-)

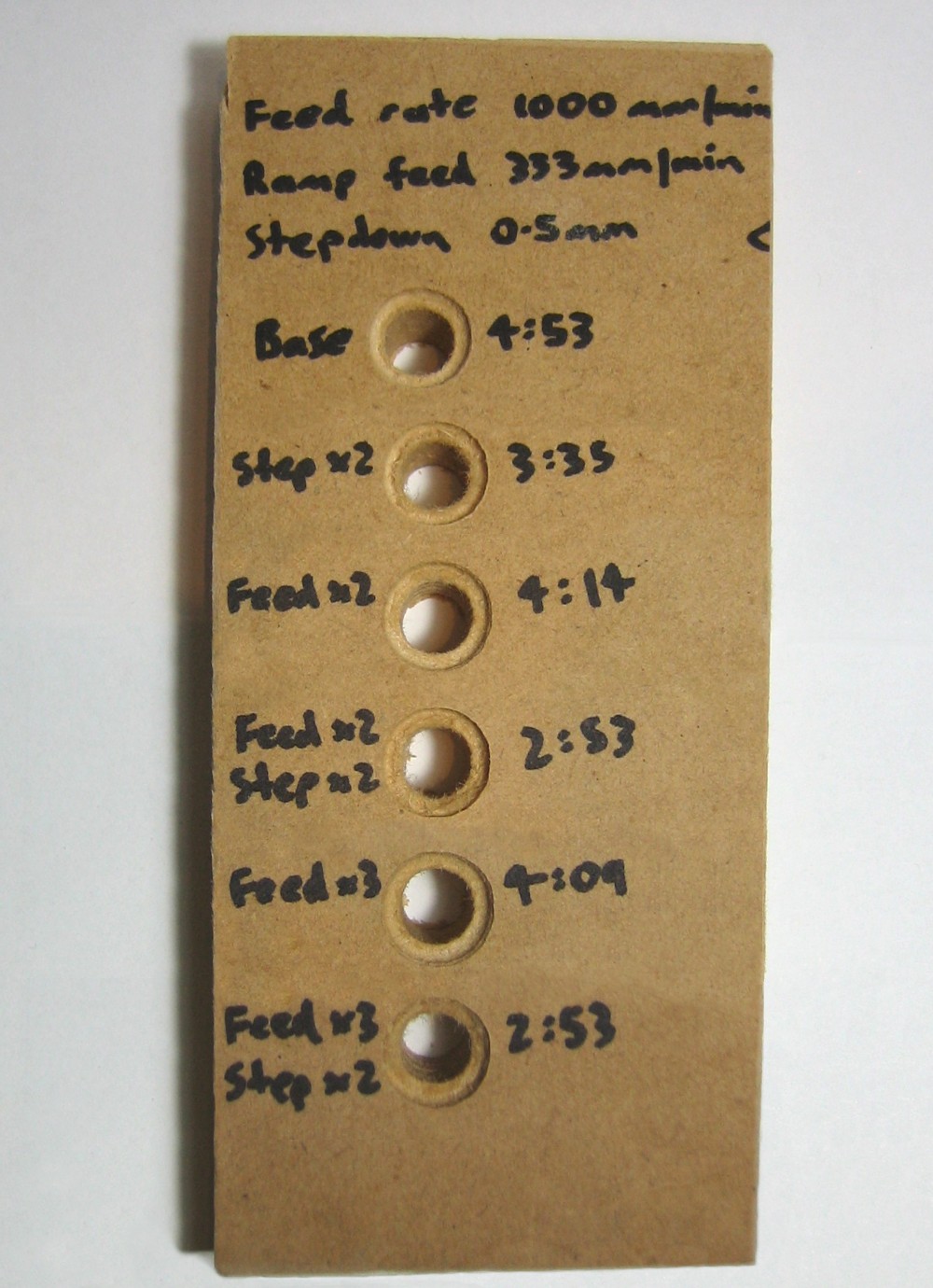

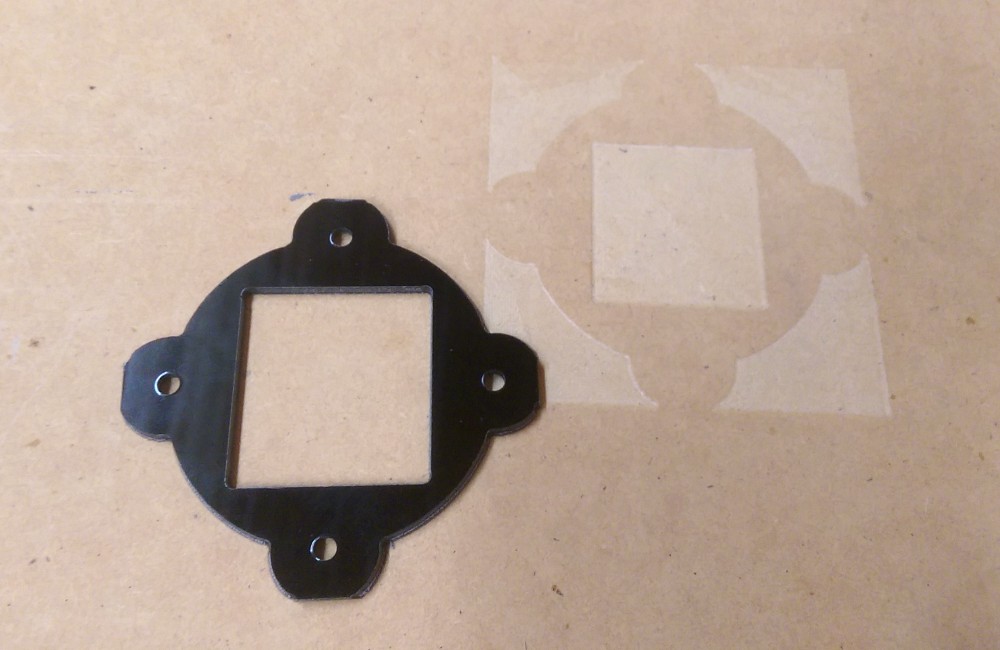

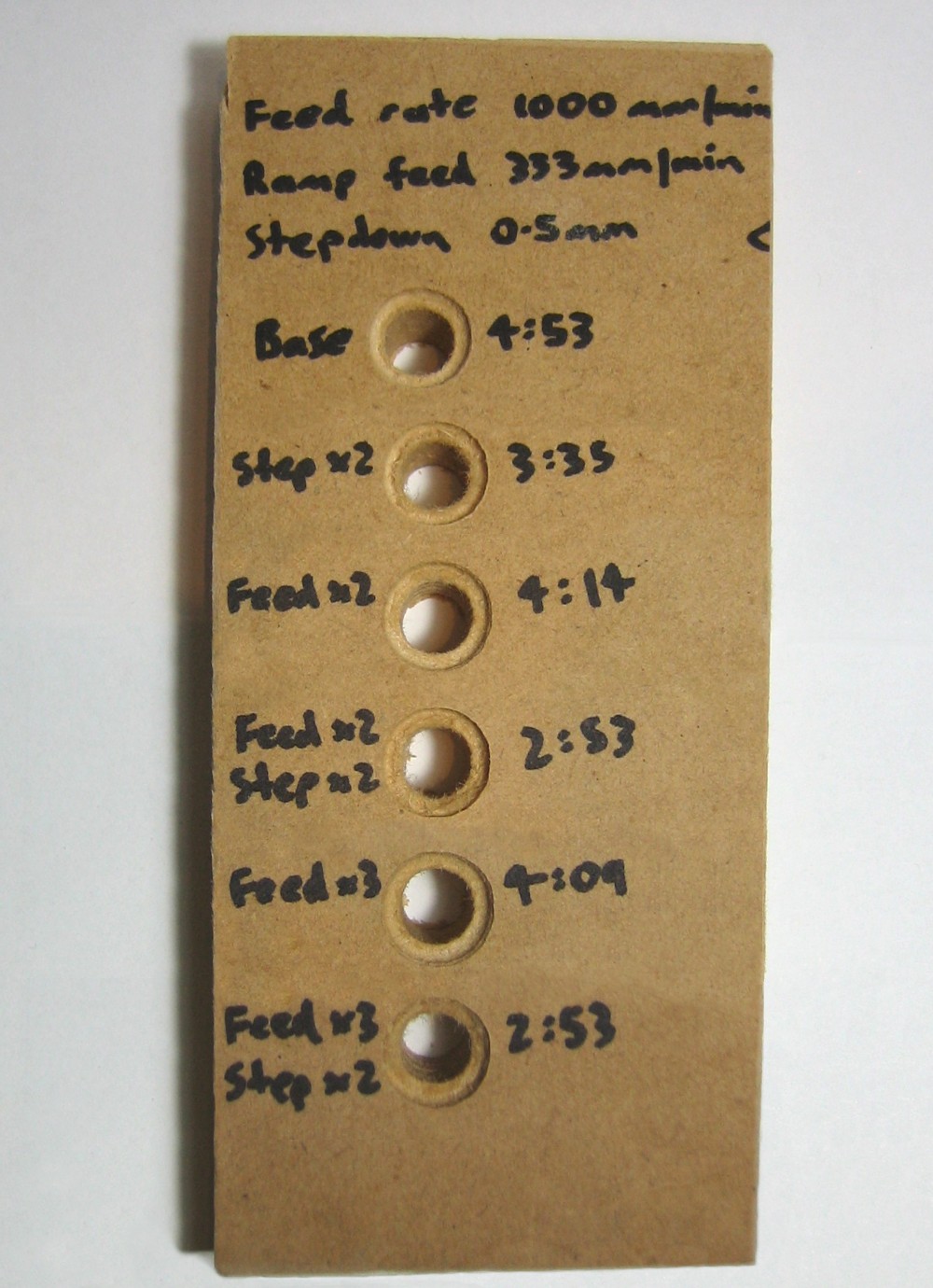

I modelled a tapered hole using measured dimensions from one of the inserts and drilled some test holes with different feed rates / pass depths to see how fast I could go and still have a decent finish. The photos below show the test holes.

For my reference, the settings used during the test runs were:

| Run # | Bit | Spindle speed (rpm) | Cutting feed rate (mm/min) | Ramp feed rate (mm/min) | Roughing step-down (mm) | Finish | Elapsed time (mm:ss) |

| 1 | 3.2mm ball-nose | 10000 | 1000 | 333 | 0.5 | Good | 4:53 |

| 2 | 3.2mm ball-nose | 10000 | 1000 | 333 | 1 | Poor | 3:35 |

| 3 | 3.2mm ball-nose | 10000 | 2000 | 666 | 0.5 | Good | 4:14 |

| 4 | 3.2mm ball-nose | 10000 | 2000 | 666 | 1 | Poor | 2:53 |

| 5 | 3.2mm ball-nose | 10000 | 3000 | 1000 | 0.5 | Ok | 4:09 |

| 6 | 3.2mm ball-nose | 10000 | 3000 | 1000 | 1 | Poor | 2:53 |

The step-down made more a difference in speed but at the loss of quality. I decided to use the settings from run #4, as increasing the feed rate from 2x to 3x didn't make that much difference in the time.

It look most of an afternoon to drill the holes. They were done one column at a time so I could take breaks during the run. Again for my reference, the spacing between the holes is 128.333mm on the x axis (770mm total), and 119mm on the y axis (1190mm total).

So many inserts to screw in...

Luckily for me, I had bought a set of ball-end hex drivers for assembling the CNC. I hate to think what it would have been like having to use an allen key. A short while later, and all 77 inserts had been screwed in.

Now that I had something to clamp to, I carved some brackets to hold work pieces in place and ordered a set of step block/clamps to clamp the pieces down vertically.